About ChuangJie

Organic waste gas treatment equipment

Organic waste gas (VOC) treatment method:

Photocatalytic oxidation, low temperature plasma, adsorption, thermal combustion, water absorption, etc. Thermal combustion includes regenerative thermal incineration (RTO), regenerative catalytic oxidation (RCO) and adsorptive desorption-catalytic oxidation (ADS-RCO).

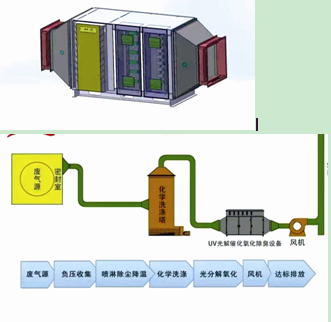

UV Photolysis Catalytic Oxidation of Organic Waste Gas Processing Unit

Photo-oxygen catalytic oxidation (POCAO) irradiates the exhaust gas with a special high-energy and high-ozone ultraviolet (UV) light beam. The molecular chains of organic or inorganic malodorous compounds react with ozone under high-energy ultraviolet (Ultraviolet) light beam to form low-molecular-weight compounds, such as CO2, H2, etc. Low investment cost, wide application range, high purification efficiency, simple operation, good deodorization effect, stable operation of equipment, small occupation of land, low operating costs, with the use of open, will not cause secondary pollution.

Organic waste gas treatment equipment

Low temperature plasma waste gas treatment unit:

Low temperature plasma produces particles with high chemical activity, such as electrons, ions, free radicals and excited state molecules. The pollutants in the exhaust gas react with these active groups with high energy, and eventually convert into CO2 and H2O, so as to purify the exhaust gas. It has a wide range of applications and high purification efficiency, especially for multi-component odor and organic waste gas which are difficult to be treated by other methods. It occupies a small area of equipment. It has high electronic energy and can interact with almost all odor and organic waste gas molecules. It has low operating cost, fast reaction, quick stopping and is ready to use. But water, dust and organic waste gas are easy to explode, and the one-time investment cost is high.