About ChuangJie

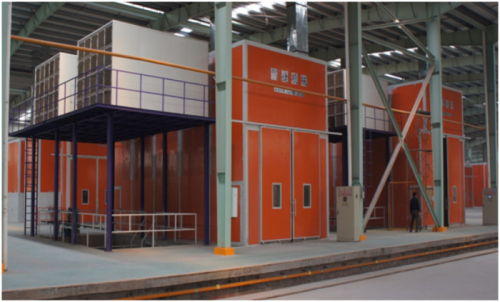

Baking room of spray paint room for large passenger cars

Brief overview of environmental protection paint baking room:

Unique large area air filtration environmental protection system:

The whole system is designed with international advanced technology. The core part of the system is high-efficiency cotton filter with three-dimensional gum spraying, which not only makes the air in the oven uniformly filtered and purified, but also guarantees that the wind speed and pressure in the operation area are in the best state. At the same time, it also creates a cleaner working environment for the sprayer and uses a variety of paints. Fog filtration device and adsorption system can reduce the emission of exhaust gas and meet the requirements of high-level spraying to the greatest extent.

House system: EPS color insulation board produced by high quality steel plate, once compound forming, good flame retardant, thermal insulation performance, low thermal conductivity. Bright colour, service life of up to 15 years. The scientific sealing technology of the interface ensures that the room is firmly sealed and effectively prevents heat loss and dust infiltration outdoors.

Large-scale spray oven industry and customer base:

1. Mainly used in large construction machinery industry: such as wind power boiler transformer bulldozer agricultural machinery

2. Transportation Industry: Train (South Railway), Automobile (BYD), Aircraft, Special Purpose Vehicle (Together Tianxin)

3. All kinds of large-scale hardware machinery industry: tile machinery

Complete spraying and baking process:

Sandblasting removes surface grease and so on -- grinding things that cannot be treated by sandblasting and then scraping ash -- spraying primer -- leveling -- baking primer -- spraying primer -- leveling -- baking primer -- spraying primer -- leveling -- spraying surface -- leveling -- baking paint -- completion

Auxiliary equipment: electric translation vehicle, three-dimensional car, lifting platform, etc.