About ChuangJie

Chuangjie regenerative catalytic purification unit (RCO)

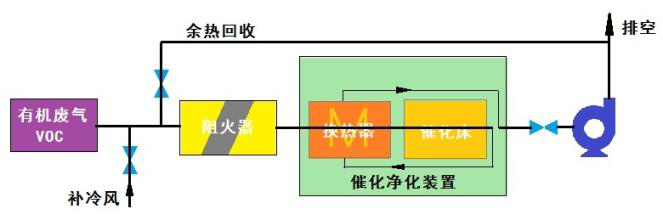

Regenerative Catalytic Purification Unit (RCO) combines the characteristics of RTO and LCO, and has the regenerative efficiency of RTO, including the low temperature catalytic oxidation technology of LCO. This product is jointly developed by many departments such as technology, production, electronic control and so on. It absorbs the advantages of similar products and is another great achievement of our company after RTO and LCO.

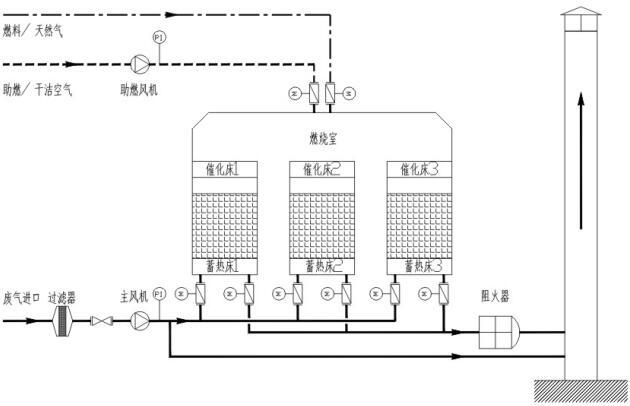

In the industrial production process, the exhaust organic gas enters the rotary valve of the equipment through the induced draft fan, and then separates the imported gas from the outlet gas completely by the rotary valve. The gas is first preheated through the ceramic filling layer (bottom layer) to generate heat storage and heat exchange, and its temperature almost reaches the temperature set by catalytic oxidation (middle layer), at which time some pollutants are oxidized and decomposed; the exhaust gas continues to heat up through the heating zone (upper layer, which can be heated by electric heating or natural gas heating), and maintains at the set temperature. Then it enters the catalytic layer to complete the catalytic oxidation reaction, that is, the reaction produces CO2 and H2O, and releases a large amount of heat to achieve the desired treatment effect. After catalytic oxidation, the gas enters other ceramic filling layers and is discharged into the atmosphere through rotary valves after heat recovery. The exhaust temperature after purification is only slightly higher than that before waste gas treatment. The system runs continuously and switches automatically. All ceramic filling layers are heated, cooled and purified by rotating valves, and heat is recovered.

RCO regenerative catalytic combustion device uses rotary valves to replace many valves in traditional equipment and complex hydraulic equipment. The removal rate of organic matter can reach over 98%, and the heat recovery rate can reach 95-97%.

Regenerative catalytic oxidation technology is a new technology based on high temperature incineration (TO) technology and catalytic oxidation (CO). It mainly adopts advanced heat exchange design technology and the selection of new animal heat materials. The exchange efficiency of traditional heat exchange design technology is generally 50-70%. Improving the heat exchange efficiency means increasing the manufacturing cost of equipment geometrically and greatly increasing the volume of heat exchange equipment. Regenerative heat exchange adopts modern advanced design concept, which makes the volume and cost of equipment effectively controlled and improves the heat exchange efficiency to 95% or even higher.

Scope of Application of Regenerative Catalytic Purification Unit (RCO)

The types of organic gases can be treated: benzenes, ketones, esters, phenols, aldehydes, alcohols, ethers, hydrocarbons, tea, benzo (a) ricins and odorous gases.Coating Production Line of Automobile, Shipbuilding, Motorcycle, Bicycle, Household Appliances, Container, etc.

Petroleum, chemical, rubber, paint, paint, paint, shoemaking adhesive, plastic products, tin printing, printing ink, cable and enameled wire production lines;

Especially suitable for enterprises requiring heat energy recovery or waste gas treatment of drying line, energy recovery can be used for drying line, so as to achieve the purpose of energy saving.

Performance Characteristics of Regenerative Catalytic Purification Unit (RCO)

Catalytic combustion is a process of catalytic oxidation of waste gases on the surface of catalysts at 200-500 C to convert products such as CO 2 and H 2. The purification efficiency is as high as 95-99.5%, and there is no secondary pollution (HOX).

Because of the advanced energy-saving technology, the energy consumption of the equipment is less than 8W Hr / NM3, which is 60 - 90% lower than that of the existing catalytic equipment. Compared with the direct combustion equipment, it does not need liquid or gas fuel, so it is convenient for enterprises to choose in various locations.

The allowable concentration range of organic waste gas in regenerative catalytic combustion equipment is 200-8000mg/NM3. Its unique design of high efficiency advanced heat exchange system ensures the effective recovery of combustion heat, so it also has outstanding advantages in the field of large flow and low concentration organic waste gas purification.