About ChuangJie

Chuangjie Zeolite Runner Adsorption Concentration and Purification Device

Zeolite Runner Adsorption Concentration and Purification Device (CJFS) is an energy-saving, non-secondary pollution purification device applied in the treatment of high-volume and low-concentration organic gas on the basis of importing foreign equipment and technology. It is efficient, stable, safe and low comprehensive operation cost. It is one of the more advanced devices for treating low-concentration waste gas at present.

Zeolite runner adsorption and concentration unit adopts three continuous processes of adsorption-concentration-desorption and incineration, which are mainly used for the treatment of organic waste gases, especially for the occasions of high air volume and low concentration. The adsorbent is made of ceramic fibers as the base material, and a honeycomb-like large disc wheel system is made. The surface of the adsorbent is coated with hydrophobic zeolite. The runner adsorption and concentration device is mainly composed of waste gas pretreatment system, runner concentration and adsorption system, desorption system, cooling and drying system and automatic control system.

Application Scope of Chuangjie Zeolite Runner Adsorption Concentration and Purification Device

1. Exhaust treatment of various painting workshops (automobile manufacturing, shipbuilding, aircraft manufacturing, steel products, resin products, etc.);

2. Exhaust treatment of various printing workshops (gravure printing, building decoration material printing, and other printing processes);

3. Exhaust treatment of dry laminated paper products and coating process;

4. Exhaust treatment in the manufacturing process of semiconductor integrated circuits;

5. Exhaust treatment in the manufacturing process of liquid crystal display (LED);

6. Exhaust treatment of lithium-ion battery manufacturing process (electrode formation process, electrolyte filling process).

Principle of Chuangjie Zeolite Runner Adsorption Concentration and Purification Unit

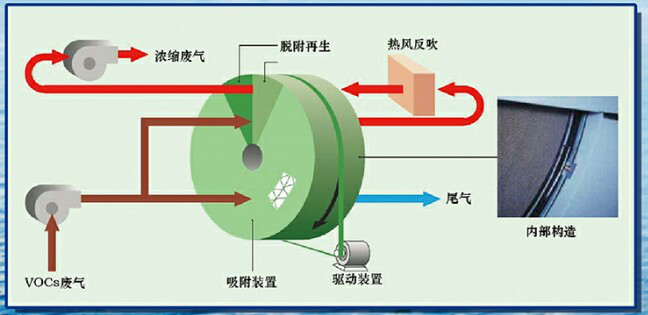

Concentration runner is divided into treatment area, regeneration area and cooling area. Concentration runner runs continuously in each area.

The treated air containing VOC passes through the pre-filter and is sent to the treatment area of the concentrated runner. VOC adsorbent is adsorbed and removed in the treatment zone, and air is purified and discharged from the treatment zone of the concentrated runner.

VOC adsorbed in the concentrated runner is desorbed and concentrated (5-15 times) by hot air treatment in the regeneration zone.

The concentrated runner is cooled in the cooling zone, the air in the cooling zone is heated and used as regenerated air to save energy.

Structural Characteristics of Chuangjie Zeolite Runner Adsorption Concentration and Purification Unit

1. High efficiency of adsorption and desorption;

2. The pressure produced by the runner adsorbing VOCs decreases, which reduces the power consumption.

3. Converting the original VOCs waste gas with high air volume and low concentration into low air volume and high concentration waste gas, the concentration ratio is 5-15 times, the specification of post-treatment equipment is reduced, and the operation cost is lower.

4. The whole system adopts modular design, which has smaller space requirements, and provides a sustained and unmanned control mode.

5. System automation control, single-key start, simple operation, and with human-machine interface to monitor important operation data.